Collection: Belt-Drive Pressure Washers

- Belt-Drive pumps feature a pulley mounted to its solid shaft and is propelled by one or more belts connected to a pulley on the motor or engine. This pulley mechanism enables these pumps to operate at a significantly lower RPM compared to a direct drive pump, typically ranging between 900-1400 RPM. The crankcase of a belt drive pump has an increased oil capacity, contributing to a cooler running temperature. This, coupled with the lower RPM, ensures the pump remains cooler than a direct drive alternative. The pump is effectively shielded from the heat generated by the engine or motor. Moreover, belts and pulleys act as vibration absorbers, reducing pump fatigue. For applications involving heavy usage, a belt drive pump is often preferred. It is important to note that this system may experience some efficiency loss due to additional friction from belts and pulleys, and occasional maintenance is required for belt adjustments. Nevertheless, under similar conditions, the belt drive system is expected to yield the longest pump life.

-

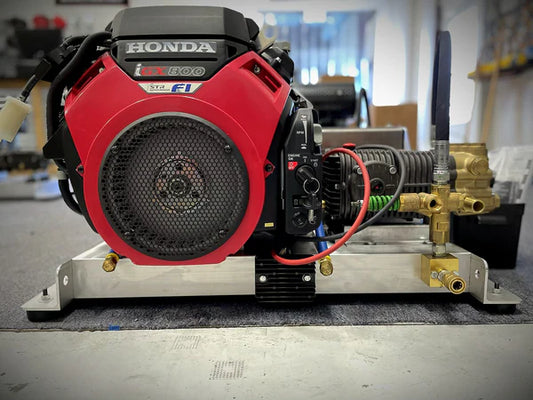

Bandit 8 gpm at 4000 psi Honda IGX800 Commercial Pressure Washer

Regular price From $4,499.00 USDRegular priceUnit price / per$4,999.00 USDSale price From $4,499.00 USDSale -

B-K8035HC Bandit 8 gpm at 3500 psi Honda GX690 With Comet

Regular price From $4,485.00 USDRegular priceUnit price / per$5,049.00 USDSale price From $4,485.00 USDSale -

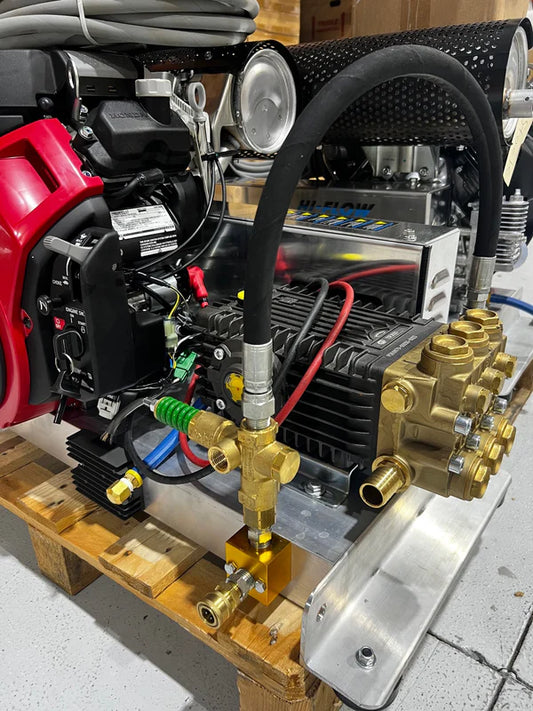

Bandit 10 GPM 3500 PSI Honda IGX800 Pressure Washer B-K1035HC

Regular price $4,499.00 USDRegular priceUnit price / per$4,600.00 USDSale price $4,499.00 USDSale -

Pressure Pro 8GPM @ 3500PSI Hot Water Skid Pressure Washer Skid

Regular price $7,999.00 USDRegular priceUnit price / per$9,299.99 USDSale price $7,999.00 USDSale -

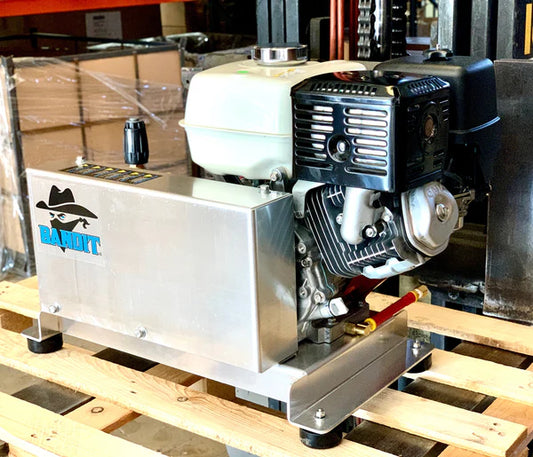

Bandit 8GPM at 2500PSI Honda GX390 With Comet Pump

Regular price From $2,299.00 USDRegular priceUnit price / per -

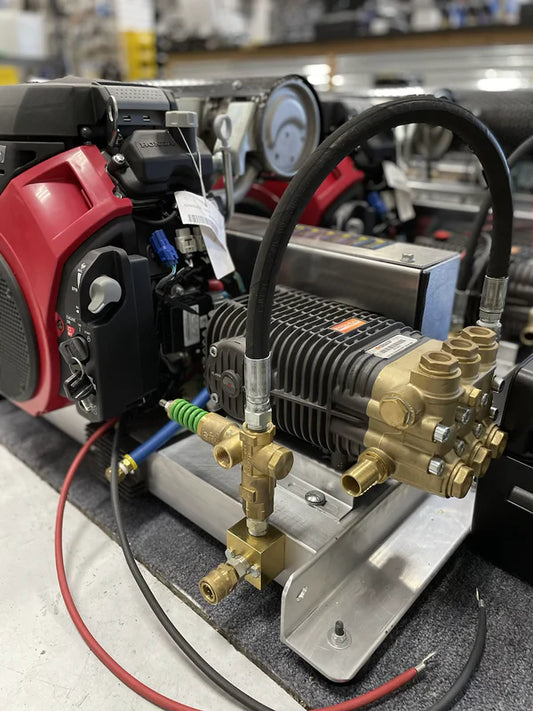

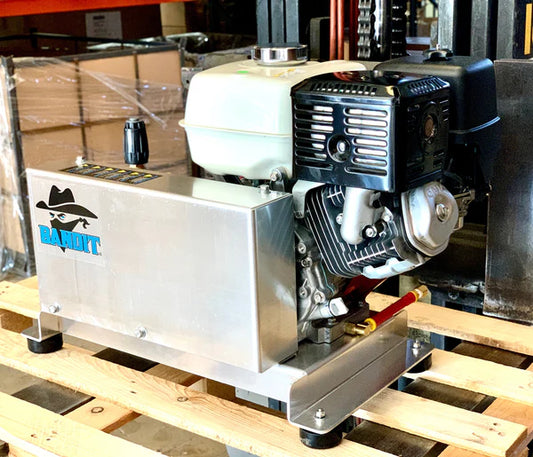

B-K8040HC Bandit 8gpm at 4000psi Honda IGX800 Commercial Pressure Washer

Regular price $4,599.00 USDRegular priceUnit price / per$4,999.00 USDSale price $4,599.00 USDSale -

Bandit 8GPM at 3500psi Honda GX690 With General Pump

Regular price $4,399.00 USDRegular priceUnit price / per$4,799.99 USDSale price $4,399.00 USDSale -

Bandit 5.5GPM at 3000PSI Honda GX390 Belt Drive With Comet Pump

Regular price From $1,999.99 USDRegular priceUnit price / per -

B-SH8035HC Bandit Smokin Hot 8GPM at 3500PSI Hot Water Skid

Regular price $8,234.10 USDRegular priceUnit price / per$9,149.00 USDSale price $8,234.10 USDSold out -

4,000 PSI - 8.0 GPM A/R PUMP WITH HONDA GX690 ENGINE

Regular price $3,849.00 USDRegular priceUnit price / per$3,999.00 USDSale price $3,849.00 USDSale