Collection: Valves

In the pressure washing industry, various types of valves are utilized to control the flow of water, regulate pressure, and manage the overall operation of pressure washing systems. Here are some common types of valves used in the pressure washing industry:

-

Ball Valves:

- Function: Ball valves control the flow of water by using a rotating ball with a bore through it.

- Application: They are often used for on/off control in pressure washing systems.

-

Check Valves:

- Function: Check valves allow water to flow in one direction only, preventing backflow.

- Application: Essential in systems where maintaining pressure and preventing water from flowing backward are critical.

-

Gate Valves:

- Function: Gate valves control water flow through a gate or wedge-shaped disc that moves perpendicular to the flow direction.

- Application: They are suitable for applications where full flow or no flow is required, not ideal for regulating partial flow.

-

Metering Valves:

- Function: Metering valves control the flow rate precisely, allowing for accurate chemical injection.

- Application: Used in systems where the controlled addition of chemicals is necessary for cleaning purposes.

-

Pressure Relief Valves:

- Function: Pressure relief valves release excess pressure from the system to prevent damage.

- Application: Critical for protecting the pressure washer and components from pressure buildup.

These valves play a crucial role in maintaining the efficiency, safety, and functionality of pressure washing equipment. The selection of valves depends on the specific requirements and design of the pressure washing system.

-

DN-10 Nickel Plated Brass Ball Valve

Regular price $34.99 USDRegular priceUnit price / per$49.99 USDSale price $34.99 USDSale -

Advanced Soft Wash Proportioner

Regular price From $544.49 USDRegular priceUnit price / per$599.95 USDSale price From $544.49 USDSale -

Proportioner Block Check Valves

Regular price From $36.99 USDRegular priceUnit price / per -

Metering Valves for Soft Wash Proportioners

Regular price From $99.99 USDRegular priceUnit price / per$99.95 USDSale price From $99.99 USD -

LV025V Banjo ¼" Female NPT Micro Valve

Regular price $29.99 USDRegular priceUnit price / per -

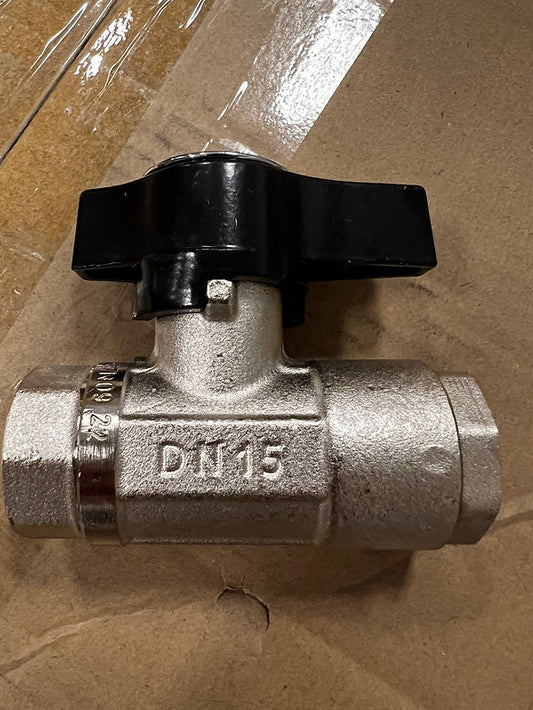

DN-15 Ball Valve 1/2" HIGH-FLOW

Regular price $65.99 USDRegular priceUnit price / per$59.99 USDSale price $65.99 USD -

CV050 ½" Check Valve

Regular price $16.99 USDRegular priceUnit price / per -

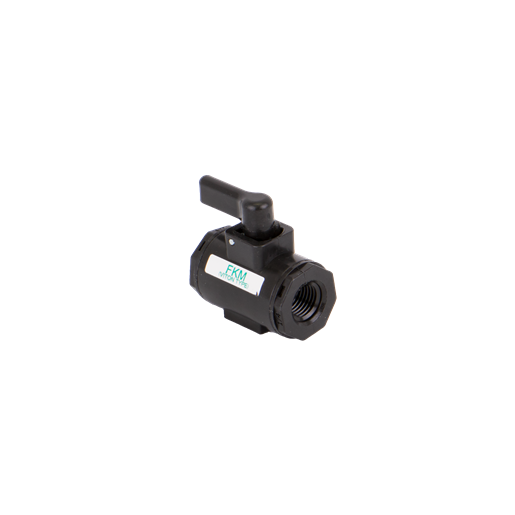

1/4" Hose Barb x 1/4" Hose Barb Series 226 PVC Ball Valve with Viton™ Seals

Regular price $20.99 USDRegular priceUnit price / per -

Downstream Injector Bypass Kit

Regular price From $124.99 USDRegular priceUnit price / per -

CV100MT Banjo 1" Male X Female NPT Check Valve

Regular price $17.99 USDRegular priceUnit price / per -

Brass Check Valve 5800 PSI 3/8in & 1/2in | Just Wash Stuff

Regular price From $29.99 USDRegular priceUnit price / per$31.49 USDSale price From $29.99 USDSale -

Banjo UV100FP 1" Full Port Single Union Valve

Regular price $19.99 USDRegular priceUnit price / per -

Sold out

Sold out2" Standard Port Valve

Regular price $55.49 USDRegular priceUnit price / per -

Banjo V100SL 1" 3-Way Side Load Valve 200 PSI | Just Wash Stuff

Regular price $55.99 USDRegular priceUnit price / per -

1" Full Port Single Union Spinweld Valve

Regular price $27.99 USDRegular priceUnit price / per -

1/4" SS check valve for injector

Regular price $37.99 USDRegular priceUnit price / per